Electronic boards assembly

For over 30 years at the service of Technology

For over 30 years, Cipriani Srl has been a reference point, throughout the national territory, in the processing of SMT Assembly and PTH Assembly on behalf of large companies and multinationals operating in the automotive, naval, home automation and security sectors.

- Technologies 4.0 to optimize processes and limit waste

- No outsourcing of work

- Warehouse with automatic storage system

- Technologies 4.0 to optimize the

- processes and limit waste

- No contract processing

- Warehouse with system of

- automatic storage

Electronic boards assembly

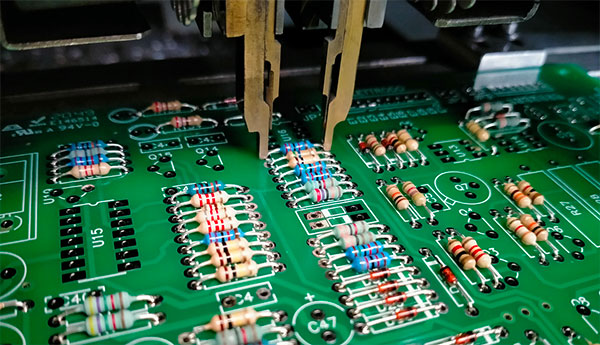

SMT Assembly and PTH Mounting

From the entrepreneurial strength of the family Cipriani was born Cipriani S.r.l., a company that in the last 30 years has been able to distinguish itself and establish itself in the Electronic sector by addressing all companies, national and international, who are looking for a partner company attentive to their needs. The core of our activity is the assembly and assembly of the components, specifically the process of Surface Assembly and the Assembly of Traditional electronic boards.

All our processes are carried out according to high standards, we use, in fact, technologically advanced machinery that automates part of the processes, a warehouse with automatic storage system and a factory of 5,000 square meters, designed to handle the best materials in every single processing step.

For several years already, we have become a point of reference in the electronics industry for many companies, both domestic and international, seeking a solid and lasting partnership that can respond promptly to the demands of a market in constant evolution.

4.0 technologies

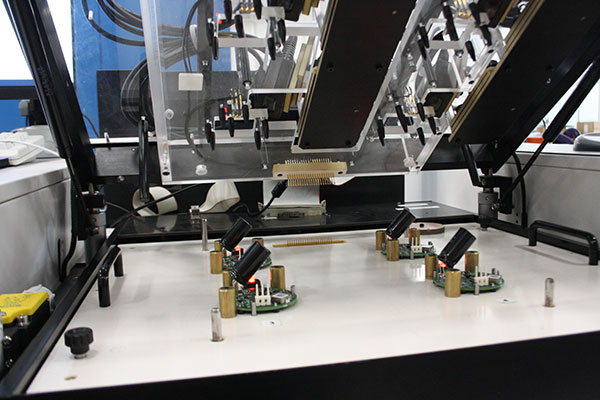

Automated machines with Technology 4.0, to optimize machining processes and limit production waste.

ESD protection

All environments, storage containers and operators' uniforms are designed for the dispersion of electrostatic charges.

single interlocutor

No outsourced processing. All stages of assembly take place in our factories, to ensure our customers an excellent product.

production line

The entire process is automated, including controls on production lines. We also have a dedicated remelting oven for each production line.

If you want to contact us for more information about our work or if you want to present your project, leave us your data and you will be contacted by our sales manager.

production processes

SMT assembly

PTH mounting

Visual inspection

Testing

Our flagship product of the year

automatic storage system

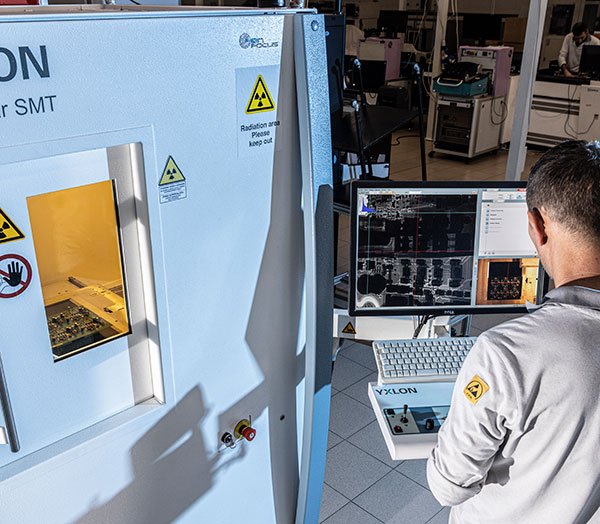

The warehouse is the starting point and the completion point of every process. Given its importance we decided to eliminate the old shelving system and introduce an automatic storage system that allows us, thein a temperature-controlled environment, to store, manage and control every single component that enters the company.

Every component that arrives in our factory, in fact, is affixed with an identification code that allows the tracking during all stages of processing. We believe that only with the use of state-of-the-art technologies and highly specialized personnel can excellence be achieved.

- raw materials warehouse

- conditioned

- X-Ray system for counting

- components

- Management of packaging/repackaging

- of materials

- traceability of materials

- (from arrival to shipment)

- through machinery

- Vacuum Sealing Equipment For Sale

- materials

- Cabinet at temperature and humidity

- checked for the preservation of

- MSL components

The areas we work with

Automotive

Naval

Domotics